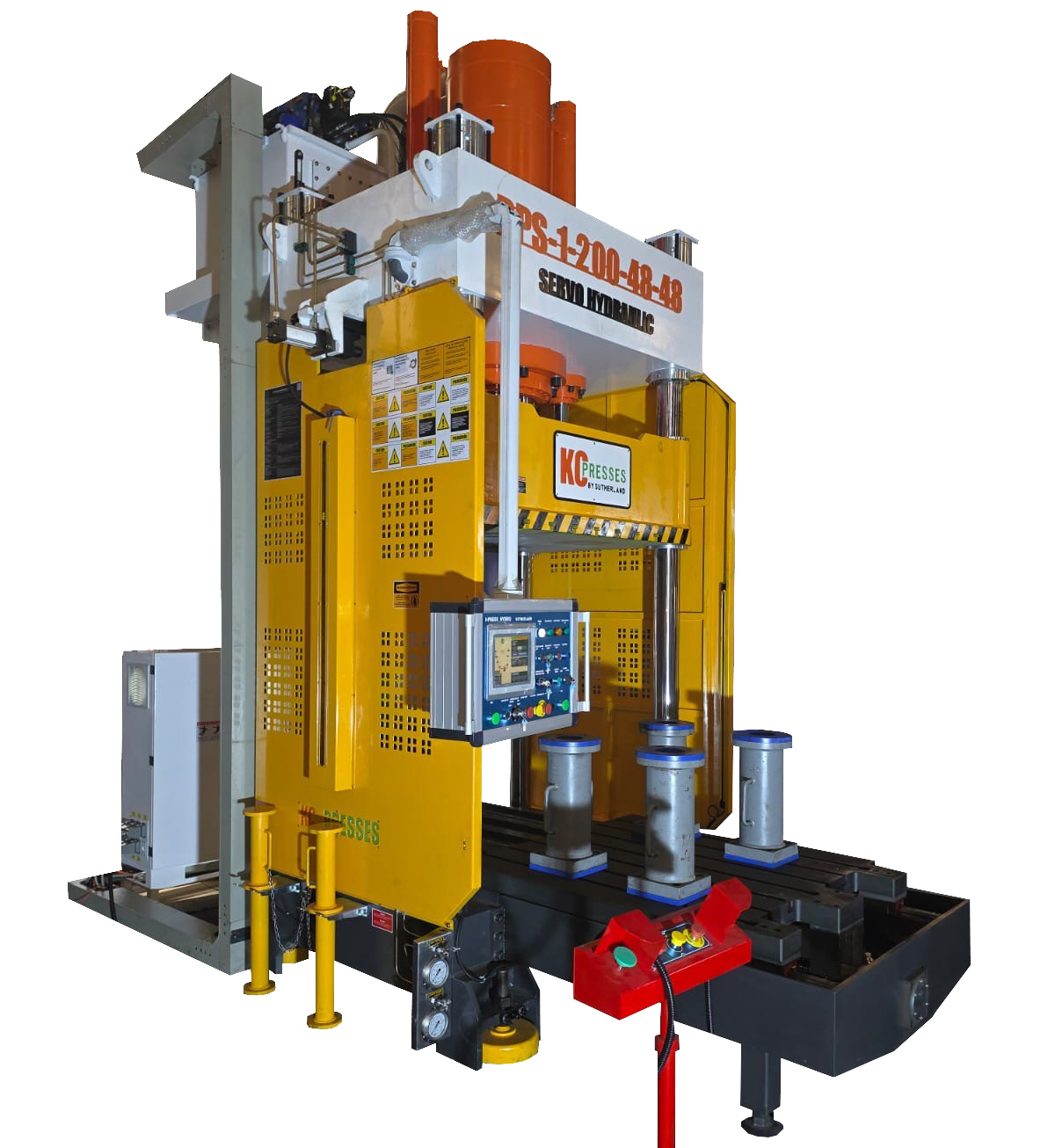

All Sutherland and KC Presses are equipped standard with our patented I-PRESS® & Automation control system, exceeding Category 3 (CAT-3) and Performance Level D (PL-D) safety standards.

All Sutherland and KC Presses are equipped standard with our patented I-PRESS® & Automation control system, exceeding Category 3 (CAT-3) and Performance Level D (PL-D) safety standards.

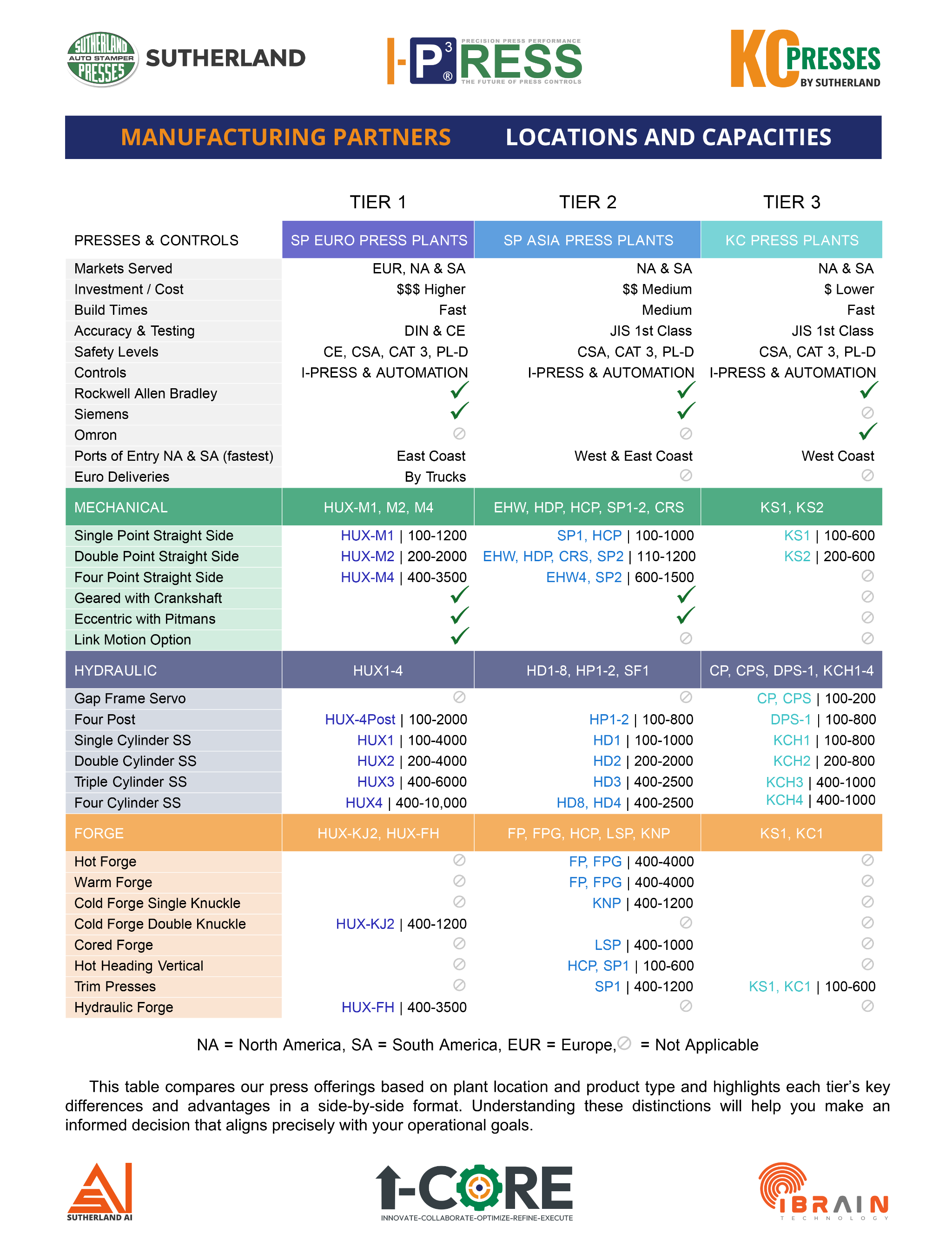

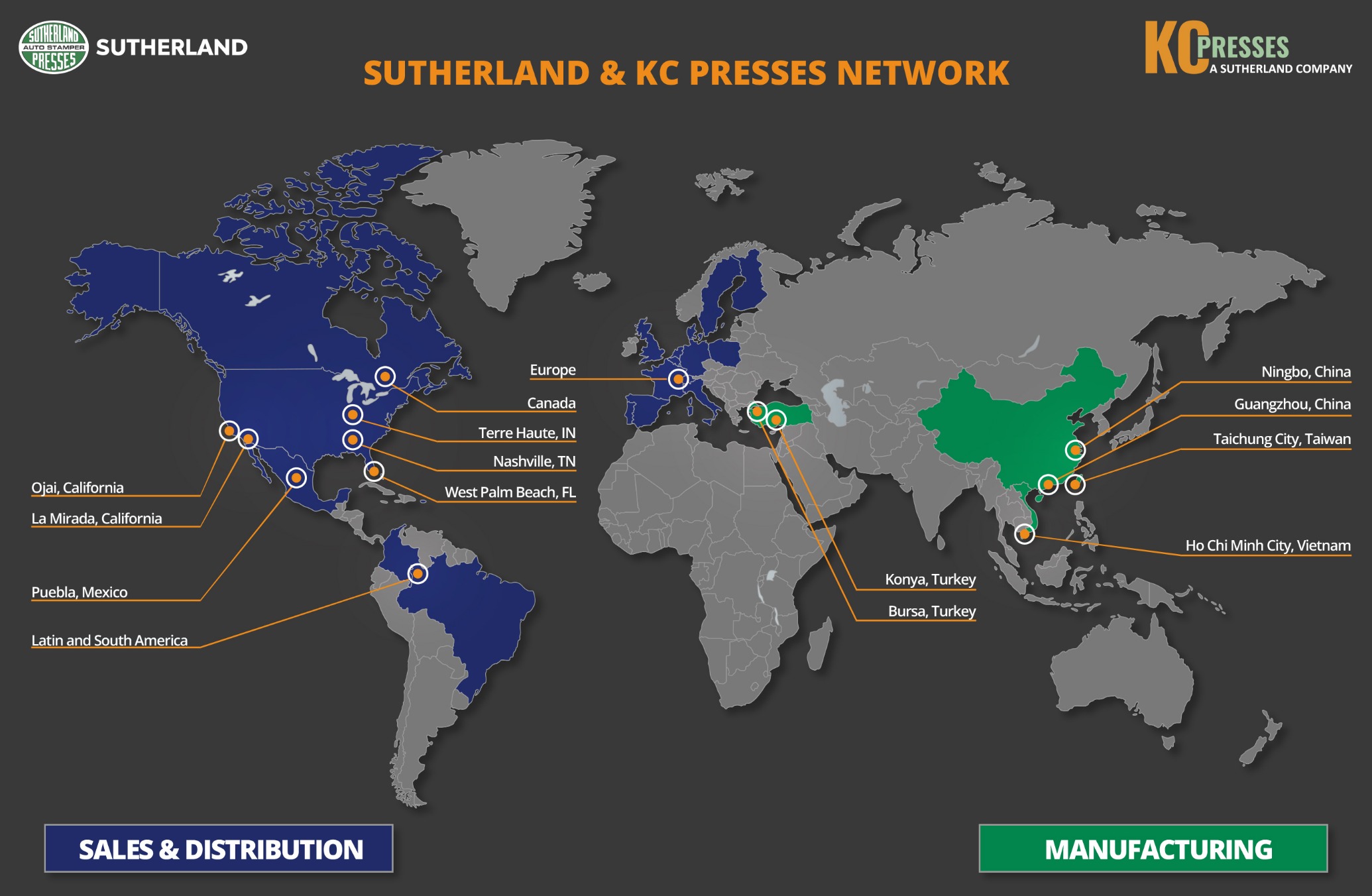

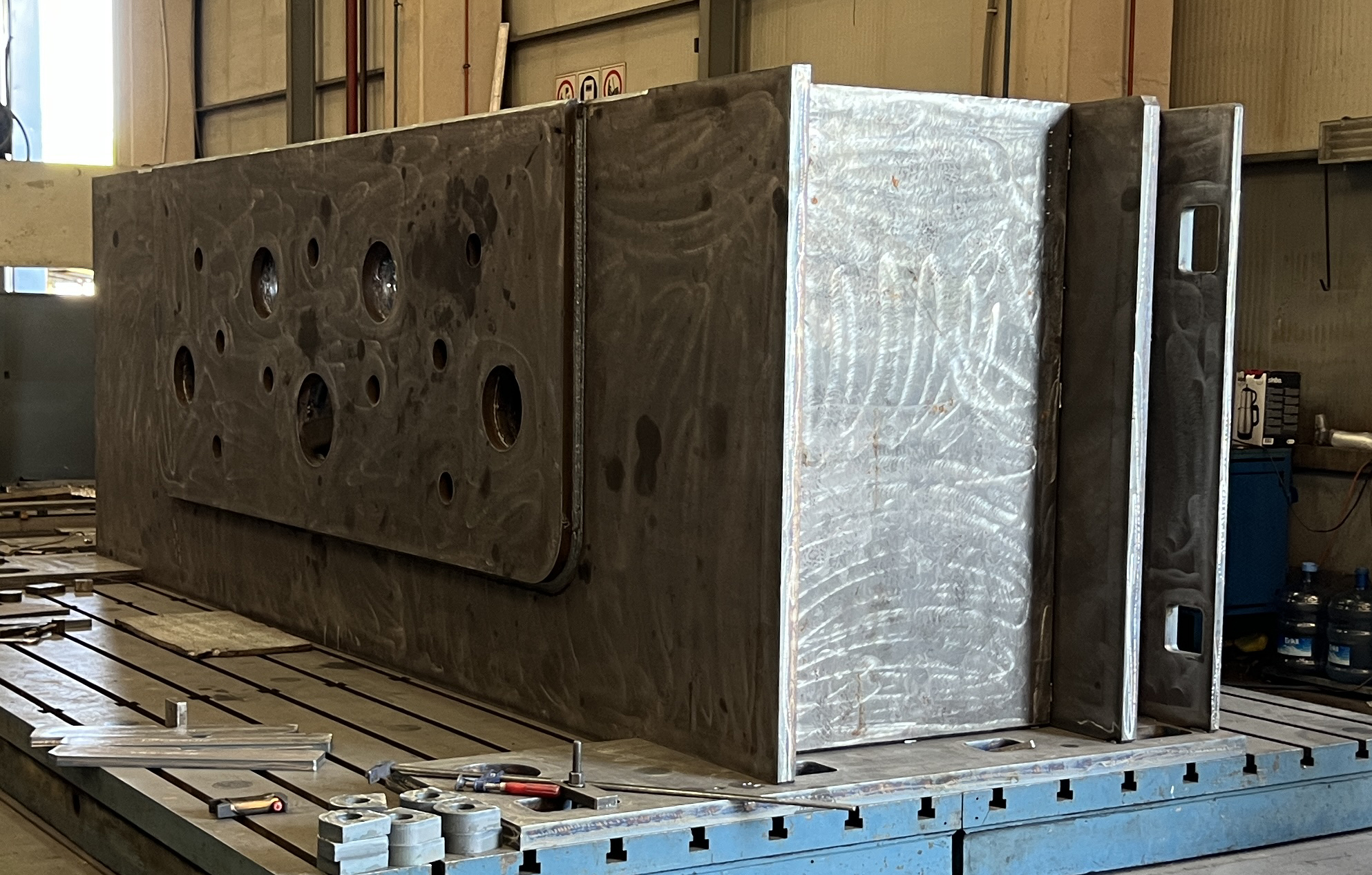

Sutherland Presses partners with world-class manufacturing facilities across Turkey, Taiwan, China, and Vietnam, offering over 3.5 million square feet of state-of-the-art production space.

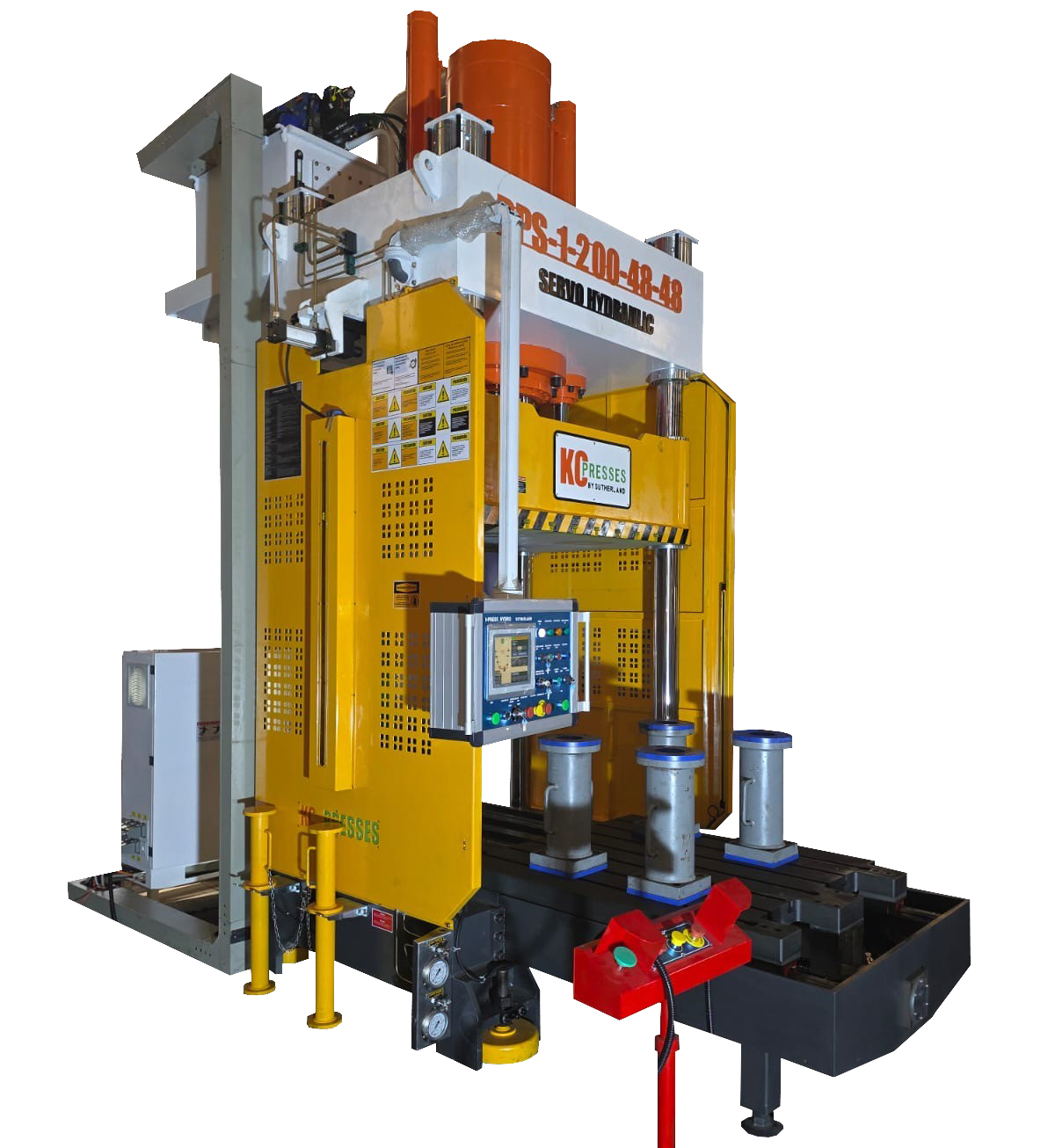

Join us in building your next servo hydraulic, mechanical, or forge press line—engineered to exceed industry standards in performance, reliability, and innovation.

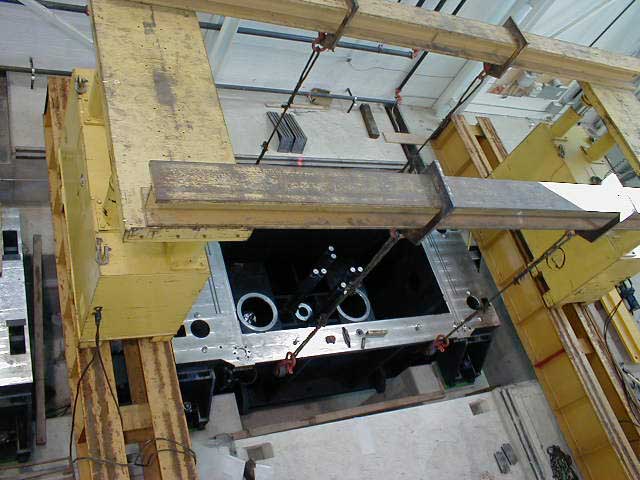

Sutherland Presses ensures every press installation is supervised by our expert technicians, covering assembly, start-up, testing, operator training, and formal acceptance turnover. Each press is cataloged by serial and model number in our secure database, enabling comprehensive lifecycle tracking for service and parts requirements.

Maximize your press uptime and performance with our Preventive Maintenance Programs, recommended annually. Each PMP includes a detailed inspection report with photographic documentation, providing actionable insights to keep your equipment running at peak efficiency. Online Service Link

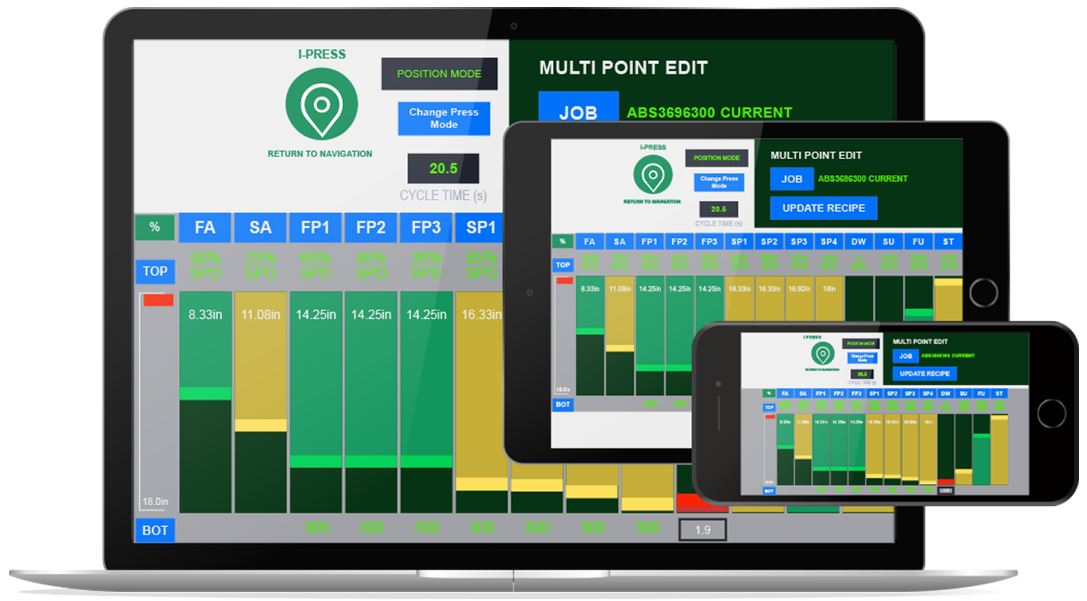

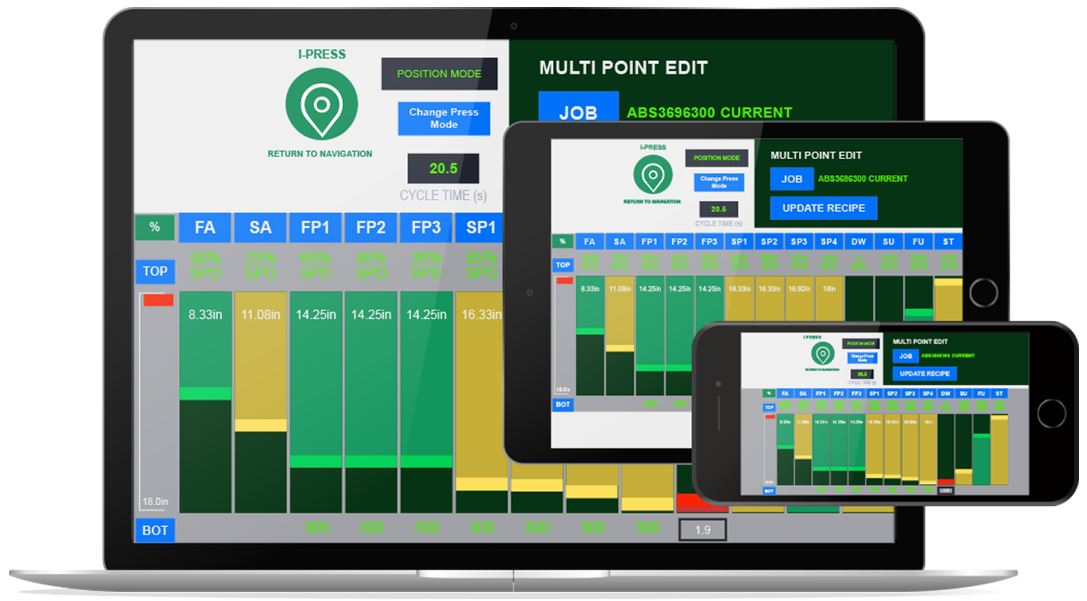

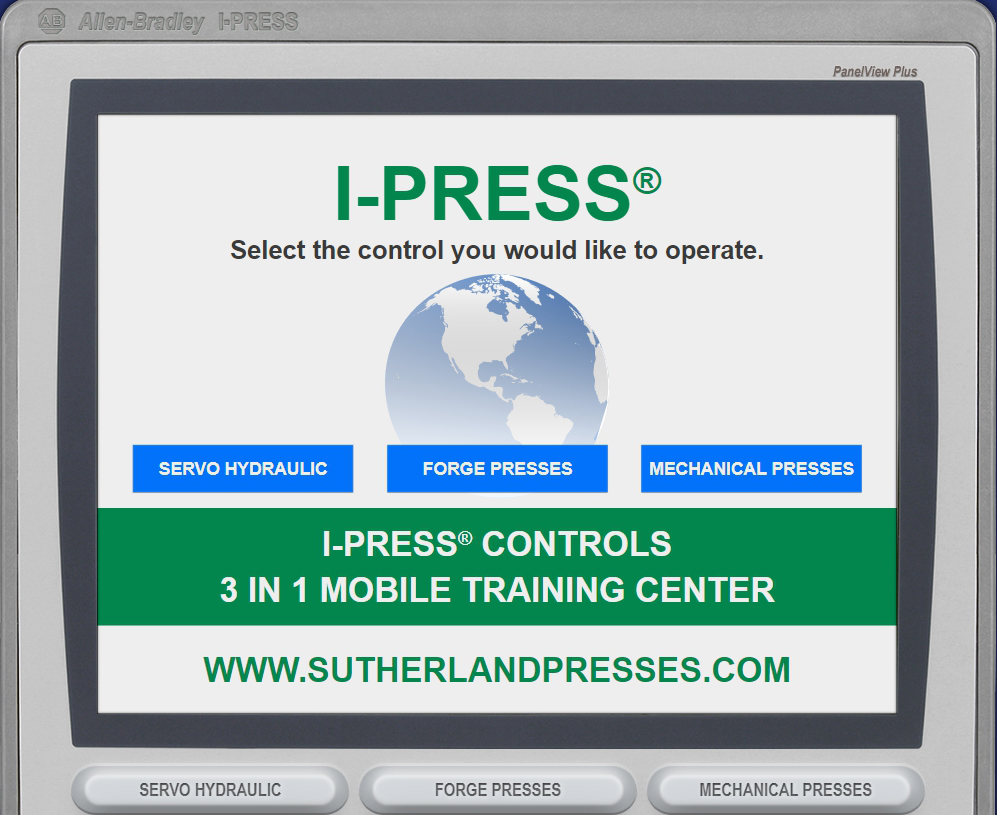

Advantages of I-PRESS® & Automation Controls

Safety Levels

Intuitive Features

At Sutherland Presses, we take pride in our exceptional wiring practices and methodologies for our Main Electrical & Operator Interface Panels, designed specifically for our I-PRESS® & Automation family of controls. Renowned for our robust fabricated steel press frames and adherence to JIS 1st Class Accuracy standards, our panels are integrated meticulously with Rockwell AB hardware to ensure unparalleled performance and reliability.

The I-PRESS system is equipped with a standard feature, Connected Enterprise, which offers secure remote connectivity through password protection. This feature enables users to benefit from remote troubleshooting, software enhancements, and customization options. It allows designated personnel, such as maintenance and engineering staff, to access the I-PRESS control system under a permission-based protocol to support the operator. Additionally, the system is capable of collecting production data.

Each system is accompanied by detailed As Built Schematics that provide a comprehensive view of the installations, facilitating seamless assessments and maintenance. These schematics are essential for understanding the intricate wiring and connections that power our presses, from Composite, Automotive and Aerospace to Appliance Manufacturing industries.

By prioritizing a "Controls First Philosophy," Sutherland Presses ensures that each component of our I-PRESS® control system is optimized for both functionality and ease of use, thereby enhancing the operational capabilities of our presses. Our dedication to quality and customer satisfaction is evident in our personalized service and support, ensuring that every Sutherland solution not only meets but exceeds industry standards.

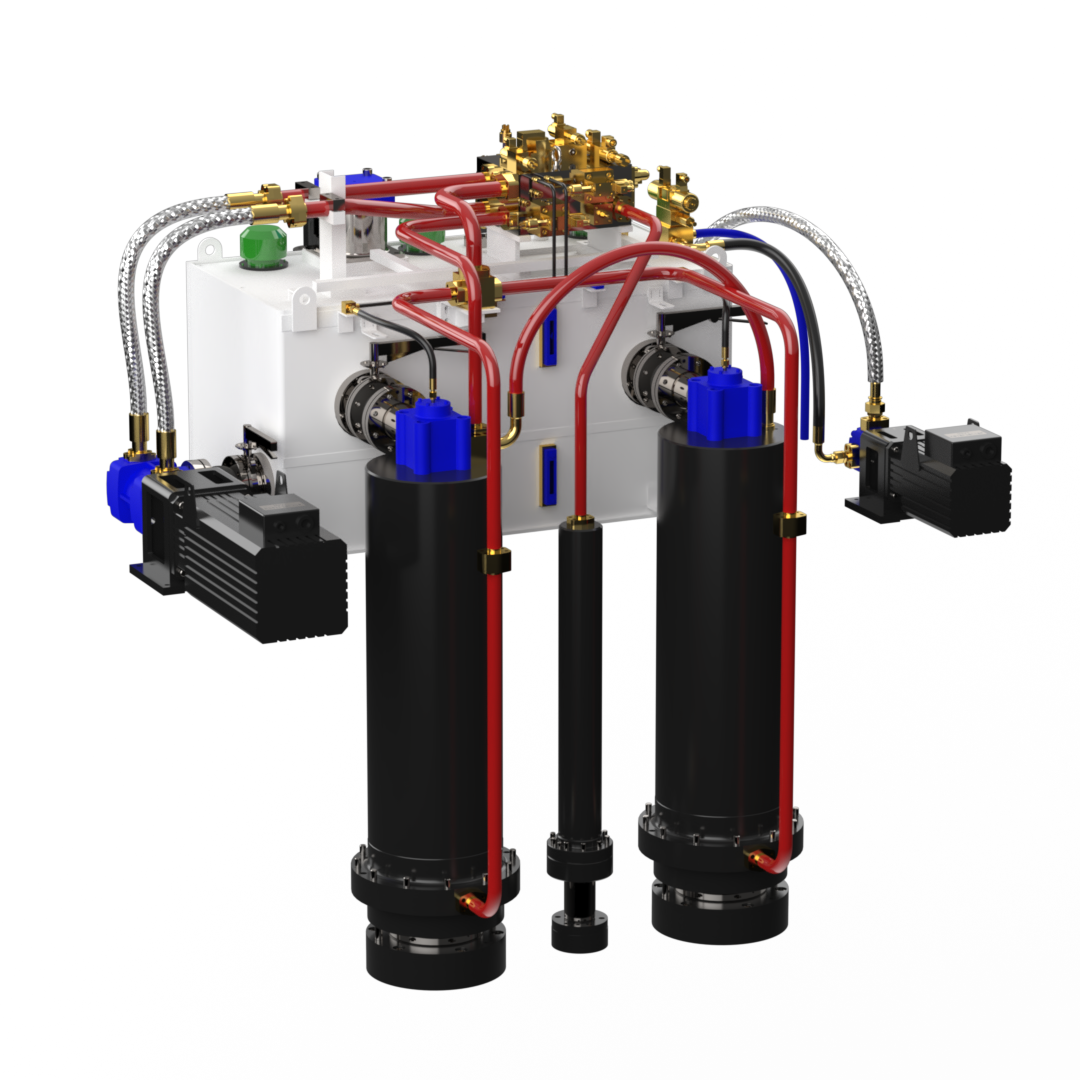

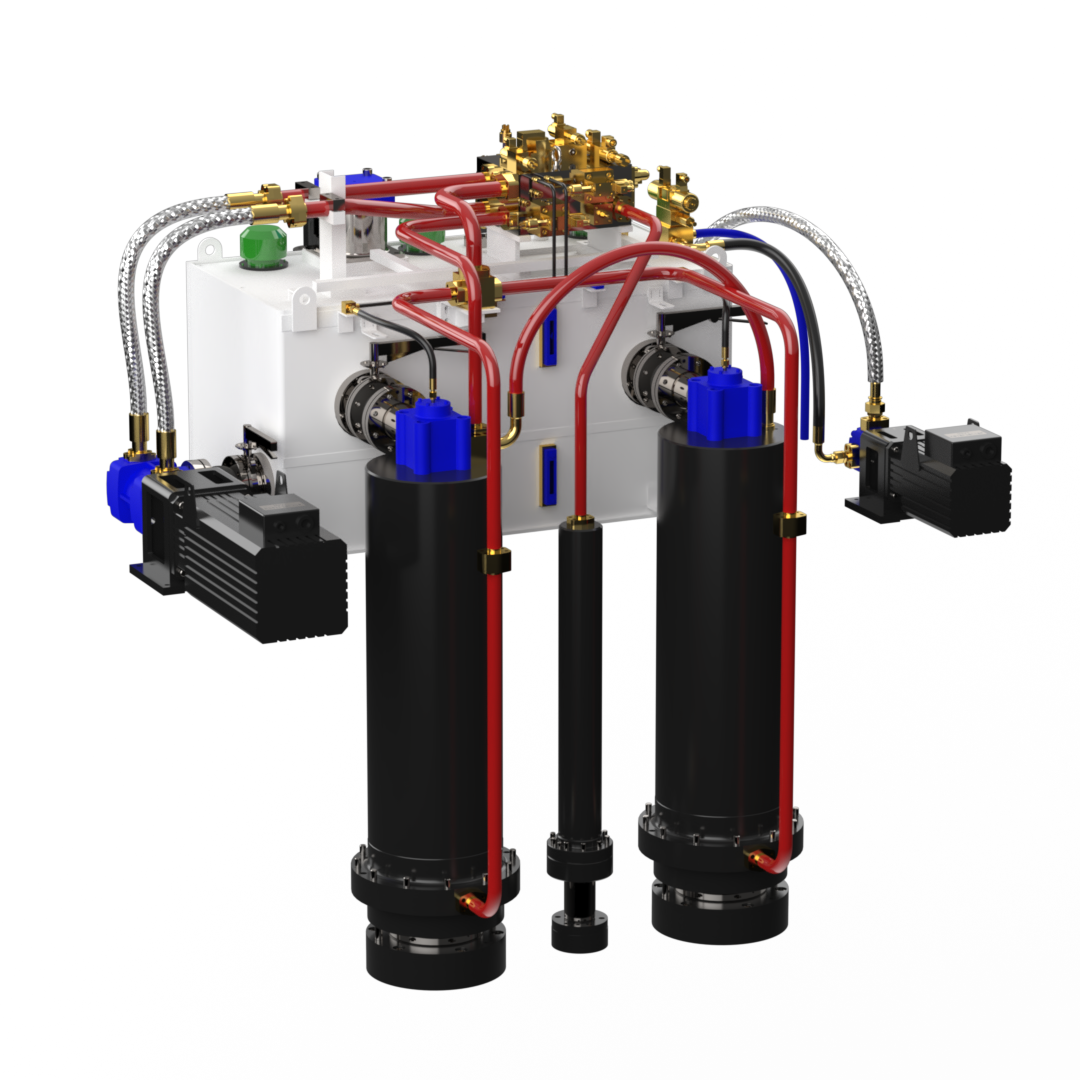

Key Features and Components:

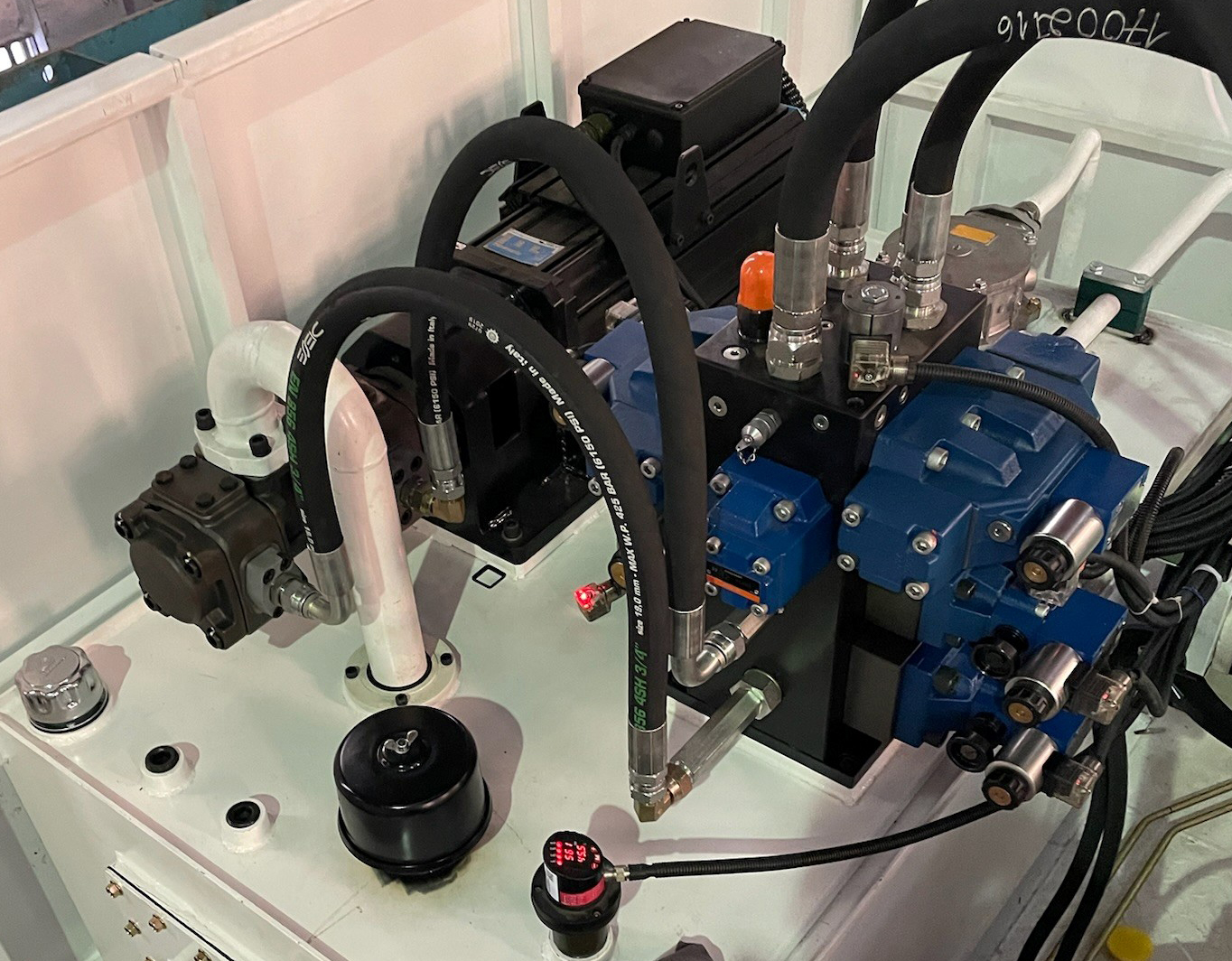

Premium Component Integration

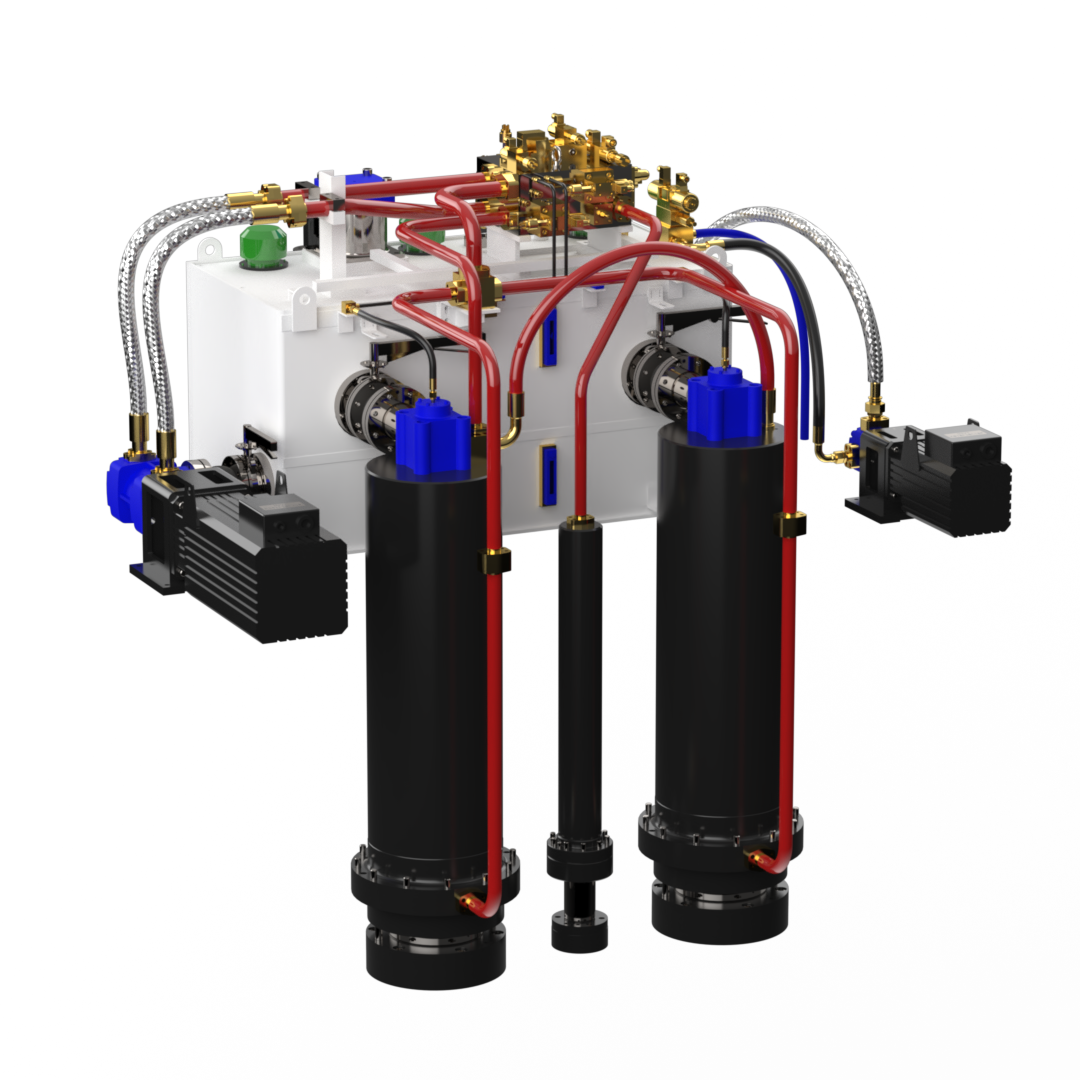

Dual Circuit Safety Valve Technology

Advanced Monitoring and Control

Maintenance-Focused Design

Comprehensive System Documentation